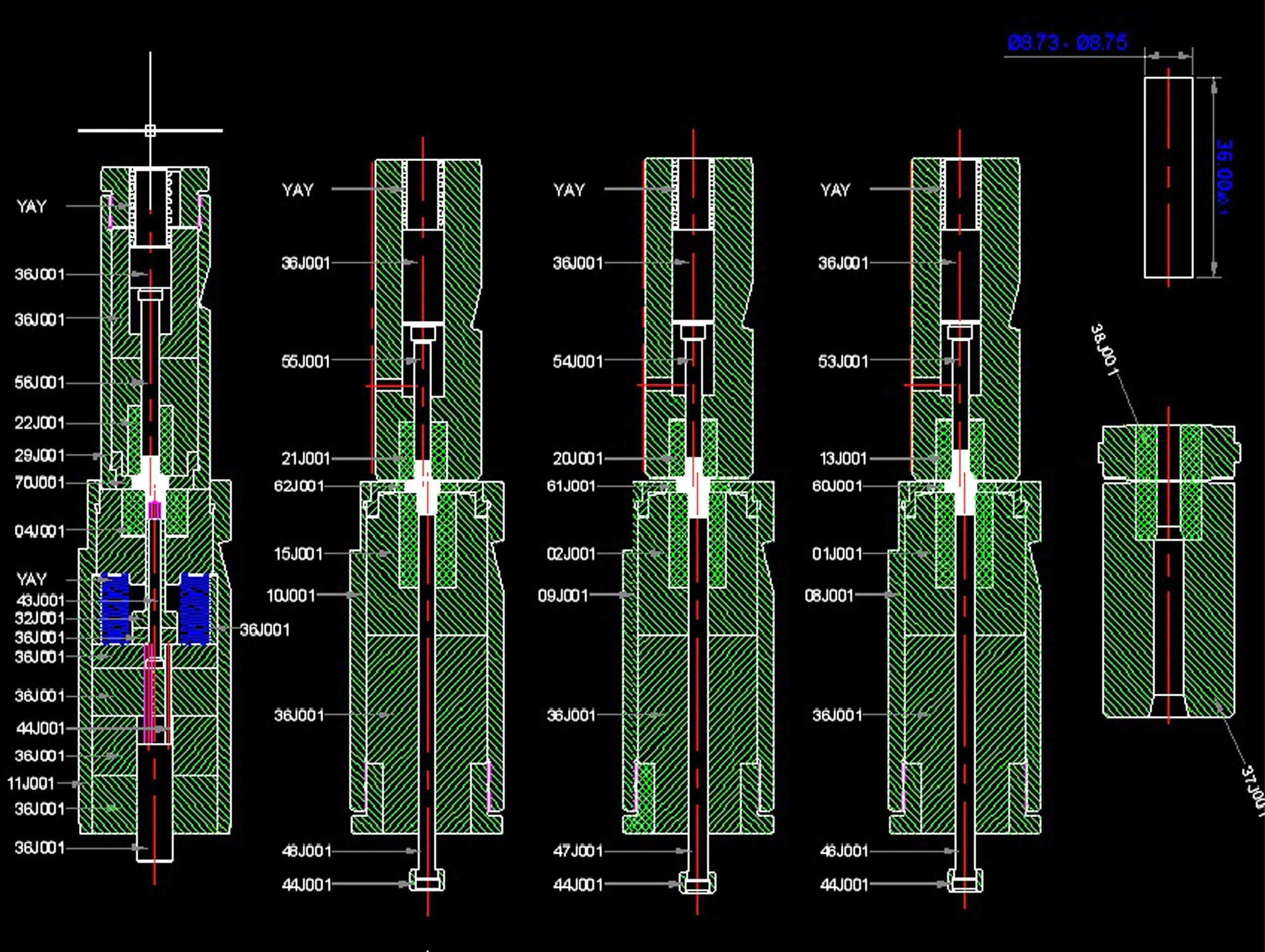

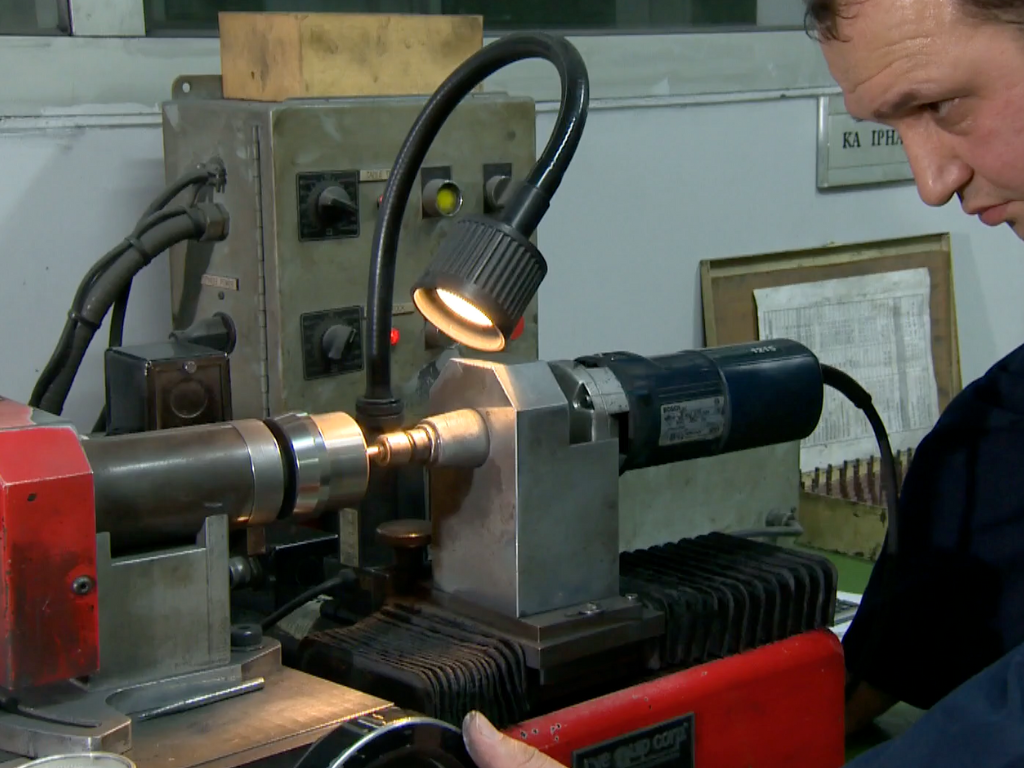

Since 2010, our company has been designing and manufacturing all cold forming dies and tool sets used in fastener production in-house.

This approach not only accelerates our production processes, but also enables us to develop tailor-made solutions for customers, maintain full quality control, and respond quickly to urgent needs.

All engineering, machining, wire EDM and maintenance operations are carried out entirely in our own toolshop.