Home › News › Decarburization Testing Added to Quality Control

Decarburization Testing Added to Quality Control

Surface carbon loss (decarburization) in fastener production can adversely affect mechanical properties, especially in high-strength grades (e.g., 10.9 and 12.9). We have added a dedicated decarburization test to our processes to determine the depth and character of decarburization from the microstructure. This allows us to verify sub-surface hardness and microstructural integrity of our parts after heat treatment and coating with greater precision.

Decarburization occurs when carbon diffuses out of the surface during high-temperature stages such as austenitizing, potentially leaving a ferritic layer or a carbon gradient. This layer can reduce local hardness and yield strength in thread crest and root areas, leading to issues like thread stripping, lower torque–tension efficiency or reduced fatigue strength. Therefore, customer specifications and relevant standards (e.g., ISO 3887, ASTM E1077; also requirements linked to ISO 898-1) set limits for free ferrite at the surface and for total/partial decarburization depth.

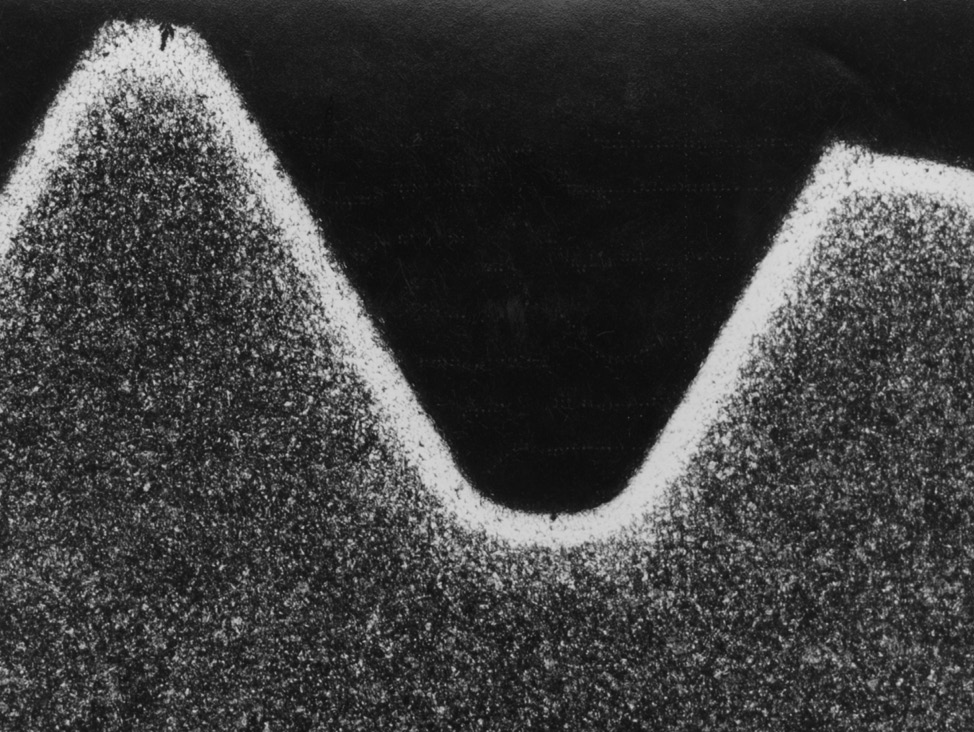

In our lab, the test is performed by sectioning critical regions (thread crest, thread root, shank), mounting, grinding and polishing to a fine finish, then etching with nital. Under the microscope at different magnifications, we distinguish complete decarburization (free ferrite layer) from partial decarburization (carbon gradient); depth is measured from the surface down to unaffected base microstructure. Measurements are taken at multiple locations and the report—complete with photos—includes depths in µm and our evaluation.

This capability provides direct feedback for atmosphere control and cycle parameters in our heat-treatment furnaces. As a result, the target microstructure is preserved through austenitizing and tempering, and an undesirable soft layer at the surface is prevented. Considered together with post-coating hydrogen relief at low temperatures, it enables us to both meet hardness targets and assure long-term durability behaviour for grades 10.9 and 12.9.